Keyboard plates tend to be 1.5mm as switches and stabilizers are designed to hook onto something with that thickness. There are a number of different companies that can manufacture keyboard plates, each supporting a different set of materials. SendCutSend and Ponoko are two laser cutting services that I've used in the United States and have had good experiences with. SendCutSend specializes in metal whereas Ponoko can cut both metal and plastic.

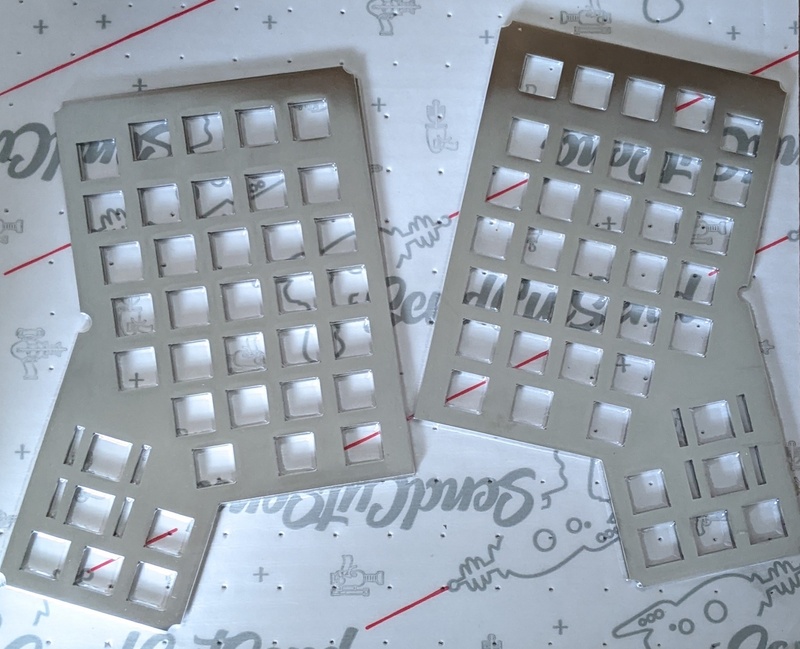

I personally went with stainless steel from SendCutSend, who gave me $50 of credit to try and review their service for this project (details below). I probably would have gone with them even if they hadn't as they had a lot of positive reviews and were the most affordable option.

One of the reasons that I went with stainless steel is that it is incredibly durable and resistant to corrosion. I don't have any concerns about scratching or breaking the plate when adjusting either the switches or the keycaps. That said, it does add a bit of weight. The volume of each plate is 17.51cm3 so two stainless steel plates weigh 275g compared to 41g for acrylic. The difference is likely not noticeable given the weight of everything else in the keyboard.

Pinging is often a concern for metal plate and I dealt with that by having an additional 4.5mm acrylic plate underneath the 1.5mm stainless steel plate. The squares and rectangles in the acrylic plate are slightly larger so everything can clip correctly to the stainless steel plate. The acrylic plate prevents the stainless plate from vibrating as it normally would. With this setup, I can't hear any pinging when typing normally. I can hear a really faint whine only if I put my head directly on top of the keyboard and continue typing that way. Your experience may vary depending on your switches and other factors.

Plate files can be found in the ergoblue/case-v2-laser repository. See the case page for information on which specific files to use. In particular, the plate can be detached from the case (higher cost, more flexibility) or integrated into the case (lower cost, less flexibility).

While SendCutSend does laser cutting for numerous metals, the ones of interest are stainless steel and mild steel as they are available in 0.060" and 0.059" thickness respectively (essentially 1.5mm). A set of left and right stainless steel plates costs approximately $43 with shipping to the US. The same costs $39 for mild steel. They have some other material in 0.063" though that is more than 1.5mm; switches and stabilizers might not clip onto those plates properly.

The price is slightly cheaper if you order two lefts (or two rights) rather than one left and one right as the plates can be used in a reversible manner. In general there will be more scratch marks on the bottom side from the laser cutting process and that ends up on the top side for the other half. Functionally it obviously doesn't make a difference.

I personally had a great experience using SendCutSend. They offer free shipping with a minimum of $29 per material. From the time I order, it typically takes a week for it to arrive at my door in NYC. One of my prototype orders (which I personally paid for) had some tolerance issues and they remade it and shipped the replacement free of charge.

In terms of quality, the cut is very sharp and clean. One of the prototype orders had some tolerance issues but I contacted them and they fixed it free of charge.

Ponoko offers metal laser cutting just like SendCutSend though their prices are a lot higher. Ponoko would make sense if you want a 1.5mm plate from a material that is not metal. If using 1.5mm acrylic, you will certainly need a second 4.5mm plate underneath as the 1.5mm would be extremely susceptible to breaking without it.

I discuss Ponoko in more detail on the case page as I purchased my acrylic case from them.